Did you know that nearly 70% of truck breakdowns are due to common truck repairs? Keeping your truck in top shape is crucial for safety and efficiency. Regular maintenance can save you from costly repairs down the road.

In this post, we’ll dive into the most frequent issues truck owners face. From brake problems to engine troubles, understanding these common repairs can help you stay ahead. We’ll also share tips on how to spot signs of trouble early. By knowing what to look for, you can keep your truck running smoothly and avoid those unexpected stops. Let’s get started on keeping your ride reliable and safe.

Key Takeaways

-

Regularly check your engine and cooling system to prevent overheating issues, which can lead to costly repairs.

-

Pay attention to clutch and suspension problems; addressing them early can enhance driving safety and vehicle performance.

-

Keep your exhaust system in good shape by inspecting it often and replacing parts as needed to maintain efficiency.

-

Ensure your battery is well-maintained to avoid unexpected breakdowns; clean terminals and check connections regularly.

-

Implement a preventive maintenance schedule that includes routine checks on all major systems to catch issues before they escalate.

-

Familiarize yourself with common truck problems to save time and money by addressing repairs promptly.

Common Truck Issues

Tire Blowouts and Pressure

Tire blowouts are a serious concern for truck drivers. Common truck problems often stem from improper tire maintenance. Inspect tires regularly to prevent blowouts caused by over- or under-inflation. Maintaining the correct pressure is crucial for safety.

Monitor tire tread depth as well. Worn treads can reduce grip on the road. This increases the risk of accidents. Replace tires that show signs of wear. Doing so maintains performance and ensures safer driving conditions.

Brake System Failures

Brake system failures rank high among common truck repair issues. Check brake fluid levels frequently to ensure proper braking function. Low fluid can lead to brake failure in critical situations.

Listen for unusual sounds when braking. Squeaking or grinding noises may indicate issues with brake pads or calipers. Schedule regular brake inspections to catch these problems early. Early detection enhances safety and can save money on repairs.

Oil and Fuel Leaks

Oil and fuel leaks can cause significant damage if not addressed quickly. Identify oil leaks promptly to prevent engine damage and costly repairs. Ignoring these leaks can lead to major breakdowns.

Monitor fuel lines for leaks as well. Fuel leaks can lead to performance issues and safety hazards, such as fire risks. Use oil additives to help seal minor leaks temporarily. This can prolong engine life until more permanent repairs are made.

Electrical System Glitches

Electrical system glitches are frequent truck issues that drivers face. Test battery connections regularly to avoid starting issues and electrical failures. A weak battery can leave you stranded.

Inspect wiring for frays or corrosion, which can disrupt electrical flow. Damaged wiring can cause various electrical problems, making it vital to check regularly. Replace fuses as needed to maintain the integrity of the electrical system. Keeping the electrical components in good condition prevents many common truck failures.

Engine and Overheating Problems

Gaskets and Engine Leaks

Gaskets play a crucial role in the engine's performance. They seal joints between different parts, preventing oil and coolant leaks. Drivers should regularly examine gaskets for wear. A worn gasket can lead to significant problems. For example, oil leaks can cause engine damage over time. Coolant leaks may lead to overheating, further complicating repairs.

Monitoring engine performance is essential. Signs of leaks include overheating or low fluid levels. If drivers notice these issues, they should investigate immediately. Using high-quality gaskets during repairs ensures a proper seal. This can improve engine longevity and reduce future repair costs.

Overheating Causes

Overheating is a common problem for truck engines. Regularly checking coolant levels is vital to prevent overheating during operation. Low coolant can quickly lead to engine failure. Drivers must inspect hoses for cracks or leaks that may cause coolant loss. A damaged hose can result in sudden overheating.

The thermostat regulates engine temperature. If it fails, the engine may overheat without warning. Routine inspections of the thermostat are necessary. Drivers should replace faulty thermostats promptly to maintain safe operating conditions.

Radiator and Coolant Issues

The radiator plays a key role in cooling the engine. Flushing the radiator periodically removes debris that can hinder performance. Dirt buildup can reduce cooling efficiency, leading to potential overheating.

Inspecting radiator hoses is equally important. Hoses can wear out over time and develop leaks. Drivers should replace any damaged hoses to ensure proper coolant flow. Using the correct type of coolant is also essential. The wrong coolant can cause corrosion inside the system.

Proper maintenance of both the radiator and coolant will enhance engine performance significantly. Following these steps helps avoid costly repairs down the line.

Clutch and Suspension Concerns

Clutch Wear and Tear

Clutch issues can lead to major problems. Monitoring clutch engagement is essential for smooth operation. Drivers should pay attention to how the clutch responds when pressed or released. If it feels sticky or unresponsive, it may need repair.

Riding the clutch is a common mistake. This practice causes unnecessary wear. It can shorten the lifespan of the clutch significantly. Drivers should avoid resting their foot on the pedal while driving. Instead, they should fully engage or disengage it as needed.

Signs of a failing clutch include slipping and difficulty shifting gears. If a driver notices these symptoms, replacing the clutch is crucial. Delaying this repair can lead to more extensive damage. Regular maintenance checks can help catch these issues early.

Suspension Noises and Joints

Suspension problems often reveal themselves through unusual noises while driving. Listening for clunks, rattles, or squeaks can indicate potential suspension issues. These sounds may signal worn-out components that need immediate attention.

Inspecting suspension joints regularly is important for safety. Worn joints can affect vehicle stability and handling. Drivers should check for any signs of wear, such as cracks or excessive play in the joints. Replacing them promptly can prevent further damage and maintain comfort while driving.

Alignment checks are also necessary for proper vehicle maintenance. Misalignment leads to uneven tire wear and affects handling. A simple alignment service can improve driving experience and extend tire life. Ideally, drivers should have their alignment checked every 6,000 miles or whenever they notice pulling to one side.

Both clutch and suspension systems play critical roles in vehicle performance. Ignoring signs of trouble can lead to costly repairs down the road. Regular inspections and timely repairs keep vehicles running smoothly.

Exhaust and Battery Maintenance

Exhaust System Tips

Regular maintenance of the exhaust system is crucial for vehicle performance. Replacing cabin air filters helps maintain air quality. Clean filters ensure better airflow, which supports exhaust efficiency.

Inspecting exhaust pipes is important. Rust or damage can lead to leaks. These leaks may cause harmful emissions. Regular checks can prevent serious issues down the line.

All exhaust components must be securely fastened. Loose parts can cause rattling noises. This not only affects comfort but can also indicate potential problems. Ensuring everything is tight improves overall vehicle maintenance efficiency.

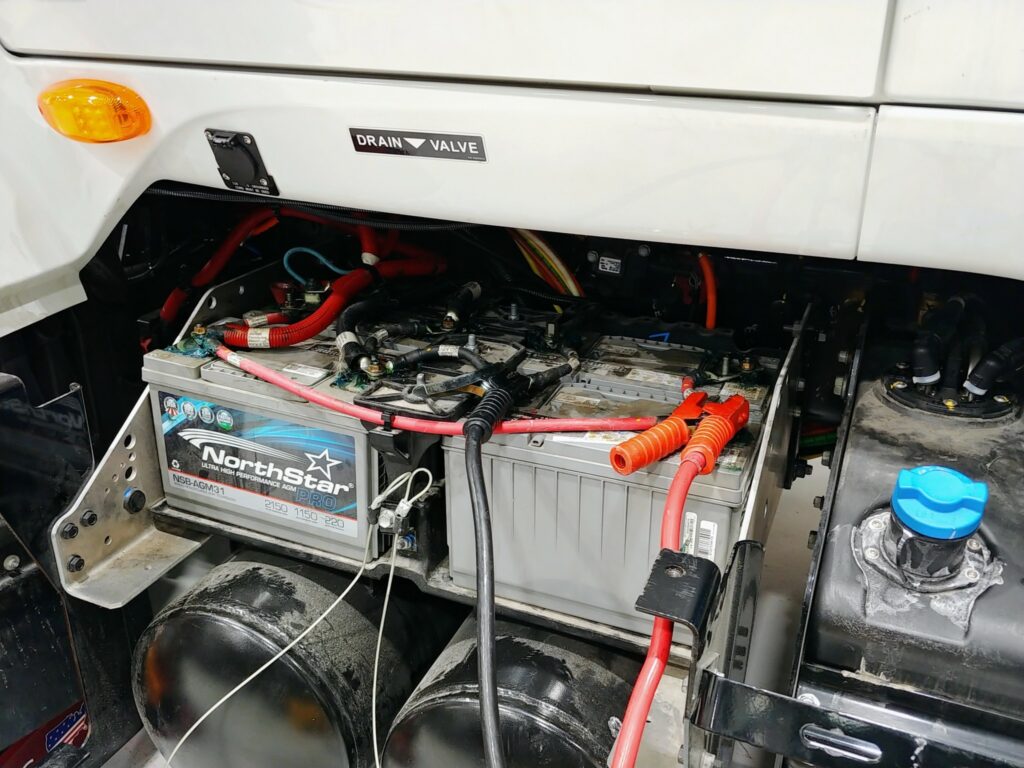

Battery Health Importance

Battery health directly impacts vehicle reliability. Testing battery voltage regularly ensures it holds a charge effectively. A fully charged battery is essential for starting the truck without issues.

Cleaning battery terminals prevents corrosion. Corroded terminals can hinder connectivity. A clean connection allows the battery to perform optimally.

Replacing old batteries is critical. Signs of age include slow engine cranking or dim lights. Addressing these symptoms early can avoid unexpected breakdowns on the road.

Proper vehicle maintenance includes attention to both the exhaust system and battery health. Together, they contribute to a smooth driving experience. Ignoring these areas can lead to costly repairs later on.

Preventive Maintenance Strategies

Regular Check-ups

Routine maintenance is essential for truck longevity. Schedule regular check-ups to identify potential issues early. This can prevent costly repairs later. Keeping detailed records of all repairs and inspections helps track the vehicle's health. These records serve as a reference for future maintenance. Following manufacturer recommendations for service intervals is crucial. It ensures that the truck remains under warranty. Consistent check-ups can also enhance performance and safety.

Early Breakdown Signs

Being aware of early breakdown signs can save time and money. Watch for warning lights on the dashboard. They often indicate potential problems that need immediate attention. Changes in vehicle performance are also significant. If you notice decreased power or responsiveness, investigate further. Strange smells or sounds should not be ignored either. Addressing these issues promptly can prevent further damage to the truck.

Timely Repairs

Timely repairs are vital for maintaining vehicle safety. Prioritize repairs based on their severity. This approach ensures that critical issues are resolved first. Seek professional help for complex problems. Experts can provide accurate diagnosis and effective repair solutions. Staying proactive with maintenance extends the life of your truck. It reduces overall costs by avoiding major breakdowns.

Final Remarks

Understanding common truck repairs can save you time and money. You now know the key issues that can arise, from engine troubles to battery maintenance. Keeping your truck in top shape means being proactive. Regular checks and preventive maintenance are essential.

Don't wait for small problems to turn into costly repairs. Take charge of your truck's health today. Stay informed, stay prepared, and keep your vehicle running smoothly. Your truck is an investment—treat it right!

Frequently Asked Questions

What are the most common truck issues?

Common truck issues include engine overheating, clutch problems, suspension wear, exhaust leaks, and battery failures. Regular maintenance can prevent these issues from becoming serious.

How can I prevent engine overheating in my truck?

To prevent engine overheating, regularly check coolant levels, inspect hoses for leaks, and ensure the radiator is functioning properly. Routine maintenance is key to avoiding costly repairs.

What signs indicate clutch problems in a truck?

Signs of clutch problems include difficulty shifting gears, unusual noises when engaging the clutch, and a burning smell. Address these symptoms promptly to avoid further damage.

How often should I check my truck's suspension?

Inspect your truck’s suspension every 12,000 miles or during routine service. Look for signs of wear like uneven tire wear or a bumpy ride to maintain safety and comfort.

Why is exhaust system maintenance important?

Maintaining your truck's exhaust system prevents harmful emissions and improves fuel efficiency. Regular checks can identify leaks or blockages early, saving money on repairs.

How can I extend my truck's battery life?

To extend battery life, keep terminals clean and tight, avoid short trips that don't fully recharge the battery, and test it regularly. A well-maintained battery reduces unexpected breakdowns.

What preventive maintenance strategies should I follow?

Follow a regular maintenance schedule that includes oil changes, tire rotations, fluid checks, and inspections of critical systems. This proactive approach helps avoid major repairs and increases your truck’s lifespan.

Broken down near Edmonton? Here are Coppertop’s Top Resources in the area:

Edmonton Travel Hotels

Edmonton Things to Do

Edmonton Places to Eat

Edmonton Weather

Not what you were looking for? Coppertop Truck Repair also offers the following services:

Heavy Duty Truck Repair

Mobile Emergency Service Truck

Commercial Vehicle Inspections (CVIP)